What are some attractive features of the permanent mold casting process?

December 12, 2025

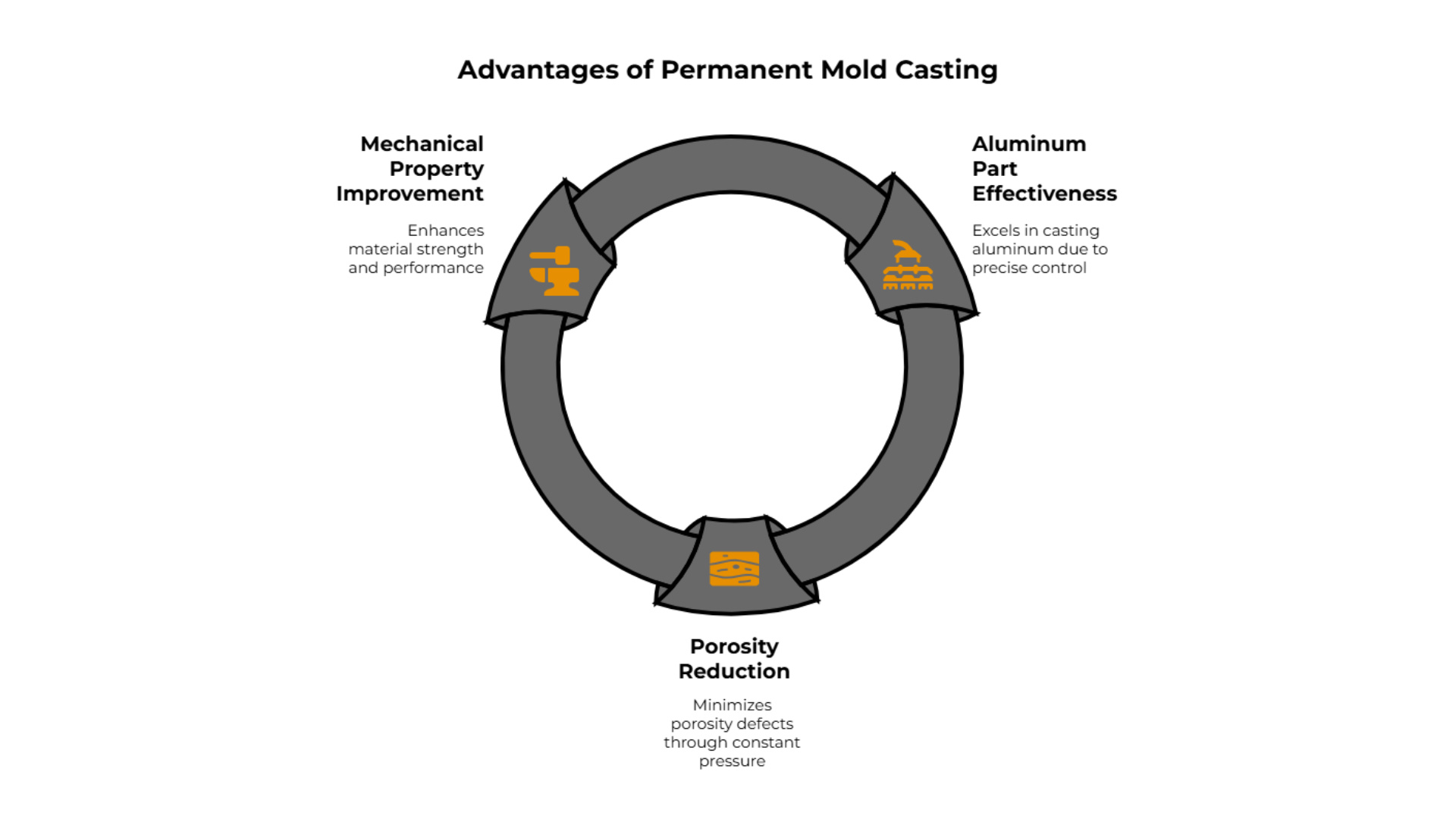

Permanent mold casting is a manufacturing solution engineered to maximize the quality and consistency of aluminum components. This method addresses many inherent defects found in traditional casting, leading to superior final products. Understanding the specific advantages is crucial for enhancing manufacturing processes, particularly in demanding fields like aerospace and automotive, which rely on precision and high integrity. To grasp the full scope of this subject, begin by exploring Permanent Mold Aluminum Casting.

Why is permanent mold casting better for aluminum parts?

Permanent Mold casting is particularly effective for aluminum due to the precise control it offers over the crystallization process. It promotes directional solidification, ensuring the part freezes sequentially from the point farthest from the gate back toward the risers. This engineered thermal gradient results in enhanced structural integrity and superior component characteristics.

The controlled filling speed, combined with the use of durable metal molds (dies), yields superior casting surface finish quality. These smooth surface finishes and tight dimensional tolerances are essential benefits sought in high-performance aluminum components.

How does permanent mold casting reduce porosity defects?

The Cause of Porosity: Hydrogen Gas

Porosity—which refers to small voids or pores within the metal structure—is primarily caused by dissolved hydrogen in the molten aluminum. When aluminum reacts with water vapor at high temperatures, hydrogen gas is generated because hydrogen solubility is significantly higher in liquid aluminum than in solid aluminum; excess dissolved hydrogen precipitates and forms gas pores during solidification, severely impairing the strength and quality of the final cast product.

Permanent mold casting successfully mitigates this risk by maintaining constant pressure during the critical solidification phase. This sustained pressure acts to suppress the formation of hydrogen gas pores. By controlling the local crystallization parameters, the process minimizes shrinkage defects and ensures excellent dimensional accuracy with tighter grain structure, which is paramount for product reliability.

What mechanical properties improve with permanent mold?

The structural refinement achieved leads to significant improvements in the material’s mechanical performance, which is a key to the permanent mold advantage. High-quality cast products depend entirely on precise control over local crystallization parameters to yield optimal mechanical values.

Optimized for Demanding Applications

In the case of critical components, such as structural parts used in aircraft or high-end automotive parts , castings must meet stringent demands. The process produces parts optimized for high ultimate strength, high yield strength , and maximized fracture strain. This high fracture strain is vital, as the component must absorb substantial deformation energy in the event of a crash. Ultimately, permanent mold casting produces aluminum parts with improved strength-to-weight ratios and overall strength compared to typical sand foundry cast alloys.

Low pressure Permanent mold vs gravity feed: What are the differences?

The fundamental distinction between the low pressure permanent mold vs gravity feed processes lies in how molten metal is introduced and held in the mold cavity.

Gravity Feed Casting

Gravity feed, also known as conventional casting, offers a straightforward, highly economical method for metal transfer by relying solely on natural gravitational force. With no need for complex pressurized systems or specialized equipment, gravity feed enables faster setup, lower operational costs, and efficient production flow. Modern pouring techniques such as automated tilt-pour and optimized gating systems have significantly reduced turbulence and improved metal flow stability, helping minimize entrapped air and oxide disruption while maintaining dependable casting quality.

Process Comparison

Compared to low-pressure permanent mold casting, which requires additional pressurization equipment, longer cycle times, and higher operating costs, gravity feed provides a simpler, leaner process. By eliminating the need for applied pressure during filling and cooling, manufacturers benefit from reduced energy consumption, fewer system components, and quicker turnaround times. These advantages make gravity feed an attractive solution for cost-sensitive and high-throughput environments.

Leverage the Advantages of Permanent Mold Casting

Ready to leverage the advantages of the permanent mold casting process for your next project? Procast specializes in delivering single source precision aluminum components with superior mechanical properties for the aerospace, automotive, industrial, and a multitude of other applications. Contact Procast today to discuss your specifications and discover how our expertise can optimize your manufacturing outcomes.