What are the limitations of permanent mold casting?

December 12, 2025

Permanent mold casting is a metal forming process known for producing components with exceptional quality and consistency, but it comes with specific constraints that limit its universal application. The key limitations revolve around the initial capital investment required for equipment and tooling, restrictions on compatible materials, and boundaries related to component complexity and volume requirements. Understanding these factors is critical for selecting the right manufacturing method.

This article explores these restrictions, including the high cost associated with the required equipment, contrasting these factors with other processes in the industry such as permanent mold casting vs die casting. By reviewing these constraints, manufacturers can determine if the inherent limitations of permanent mold aluminum casting are compatible with their project’s needs and goals.

What type of aluminum is used for casting?

Aluminum alloys primarily of the 3xx.x series are the most commonly used for permanent mold casting, being specifically designed for that purpose. The Aluminum Association system designates these as alloys containing silicon plus copper and/or magnesium. These alloys are favored for their excellent fluidity and castability, along with mechanical properties suitable for demanding applications.

Other alloy series, spanning 1xx.x (minimum 99.00% aluminum) to 8xx.x (tin), are also viable depending on the desired properties, such as resistance to corrosion or improved strength. When planning for early-stage component verification or producing a small test run, manufacturers might rely on prototype aluminum casting using readily available alloy forms that mimic the final production material.

What are the disadvantages of permanent mold casting?

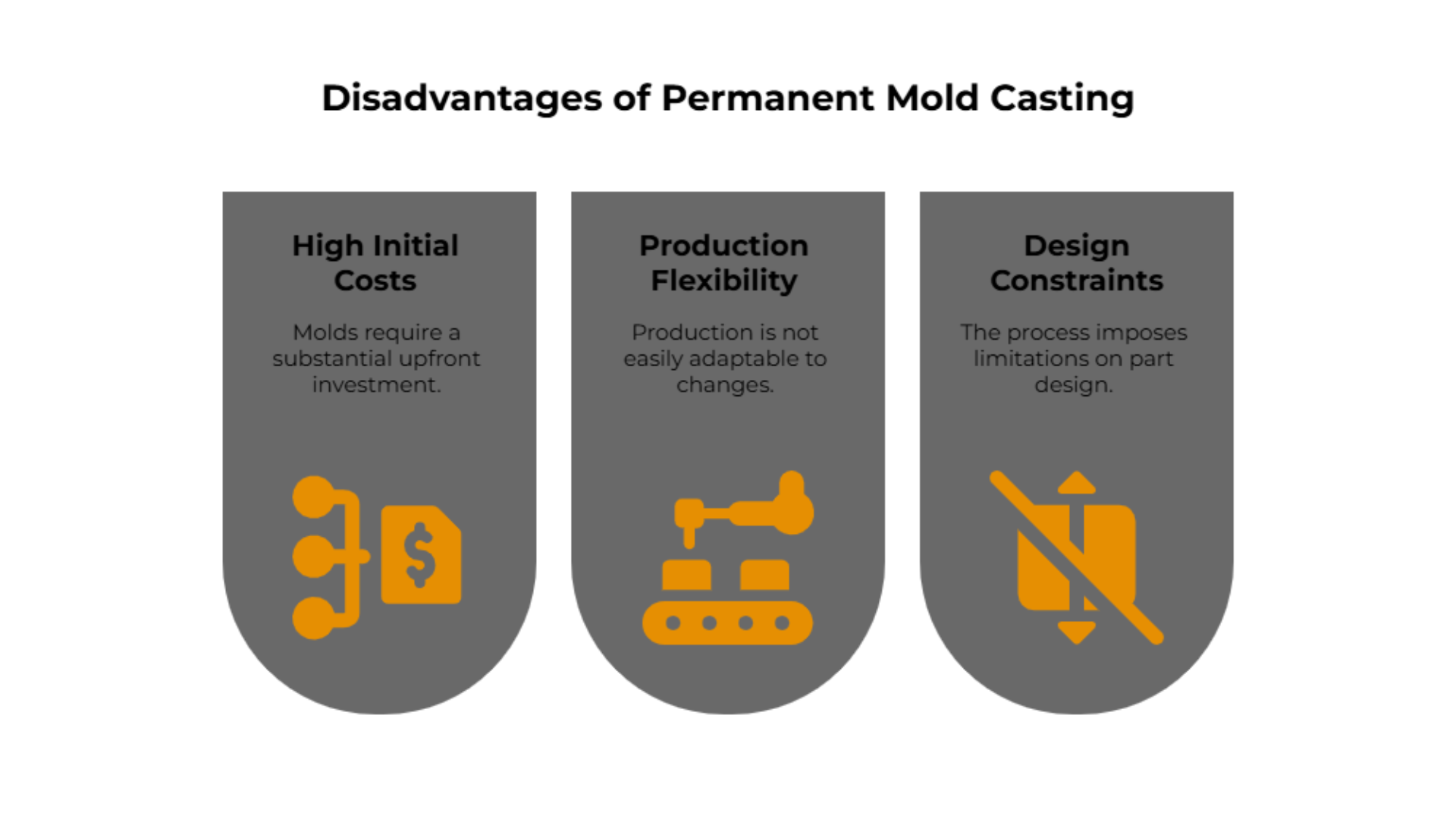

The primary disadvantages of permanent mold casting can be summarized as follows:

- •High initial tooling costs.

- •Limited production flexibility.

- •Certain design constraints.

together sum up what are the disadvantages of permanent mold casting. The molds, made from durable materials like steel or cast iron, demand a substantial upfront investment, making the process uneconomical for low-volume runs.

Although faster than sand casting, permanent mold casting cools more slowly than die casting, and is best suited for medium annual volumes of 500–50,000 pieces. Additionally, cast alloys often have lower elongation and strength, and complex parts may require sand cores, raising costs and reducing the efficiency of the permanent mold process.

What is the lifespan of aluminum molds?

The expansive lifespan of molds used in permanent mold casting is often measured across tens of thousands of cycles, though actual longevity is highly variable. While the description “aluminum molds” is generally used, the tooling itself is typically made of robust metals like steel or cast iron to handle the extreme thermal conditions of repetitive casting. Mold degradation and eventual lifespan limitations are primarily influenced by thermal fatigue, high temperatures, and the aggressive nature of the molten alloy.

Since the process requires durable tooling that is more expensive than sand molds, longevity is a key factor in offsetting the initial investment. For permanent mold casting, the recommended volume requirements are perfect for medium annual volumes ranging from 500 to 50,000 pieces, ensuring productivity and cost-efficiency.

What are the cons of cast aluminum?

The disadvantages of cast aluminum products primarily relate to inferior mechanical properties, particularly when compared to products manufactured using wrought processes, such as forging or extrusion. Cast alloys typically have lower elongation and strength, especially in fatigue, compared to wrought alloys.

This difference is partly due to potential defects created during casting, such as microshrink holes or porosity. While permanent mold casting minimizes these defects compared to sand casting, the inherent structure of cast alloys, which contain larger amounts of silicon and copper, results in a heterogeneous structure with brittle secondary phases. Successfully weighing these trade-offs is essential for manufacturers seeking the optimal balance between initial investment and final product performance, which forms the basis for studying the advantages and disadvantages of metal casting.

| Process Constraint | Description |

|---|---|

| High Initial Investment | Tooling must be machined from high-strength steel or cast iron, resulting in substantial upfront costs. |

| Mechanical Properties | Parts exhibit lower strength, elongation, and fatigue resistance than wrought aluminum. |

| Tolerance Achievement | Linear tolerances are typically 0.010” to 0.025”, with tighter tolerances achieved through post-casting CNC machining. |

Permanent mold casting machine price

The notably high permanent mold casting machine price and the specialized tooling costs require careful financial planning, as they represent the largest initial capital expenditure for a permanent mold casting project. The machinery must be durable and capable of operating continuously, which inherently drives up the cost compared to simpler casting apparatus. This substantial investment means the process is only cost-efficient if the costs can be spread across a large enough production run.

As a result, companies must ensure they have firm medium-to-high volume orders to justify the expenditure. Analyzing the total cost, including the permanent mold casting machine price and tool fabrication, is necessary to determine if the resulting component price remains competitive. It is for these reasons that Procast continually invests in the latest cutting edge casting and mold making equipment in order to offer our customers industry leading quality and pricing.

Conclusion

Permanent mold casting is an excellent choice for projects requiring high-quality, repeatable components, provided the design accommodates the inherent trade-offs. The high cost barrier, primarily driven by the equipment and tooling, limits its viability to medium-to-high volume runs that allow the investment to be amortized efficiently. It is for these reasons that Procast continuously invests in the most efficient and cutting edge equipment to produce your castings.

Choosing this process requires a clear understanding of these constraints relative to product requirements – especially regarding mechanical properties – where cast aluminum is often surpassed by wrought alternatives. For an inside look at the technology powering precision and performance, explore our detailed guide on Permanent Mold Aluminum Casting.

Ready to explore the benefits of permanent mold aluminum casting here at Procast for your next project?

for expert insights and services that can transform your manufacturing process.