In the aluminum manufacturing industry, selecting the appropriate casting process is critical for achieving optimal results. Two prominent methods—permanent mold aluminum casting and die casting—offer distinct advantages and applications.

This article explores the fundamental differences between these processes, examining their methodologies, materials, and suitability for various projects. By the end, you’ll have a clearer understanding of which method aligns best with your manufacturing needs.

What is the difference between die casting and permanent mold casting?

Die casting and permanent mold casting are both effective techniques for producing aluminum components, but they differ significantly in their processes and applications. Understanding the nuances of permanent mold casting vs die casting is essential when choosing the right manufacturing method for your project.

Key Differences

• Mold Type: Die casting utilizes a two-part steel mold, while permanent mold casting employs a non-expendable metal mold. The longevity of permanent molds frequently results in reduced costs over time, especially for medium- to high-volume production runs.

• Pressure: Die casting operates under high pressure, ensuring rapid filling and solidification. In contrast, permanent mold casting relies on gravity to fill the mold. This pressure difference can significantly affect the quality and characteristics of the final product, influencing factors like surface finish and dimensional accuracy.

• Applications: Die casting is favored for intricate designs and high-volume runs, while permanent mold casting is better suited for larger, simpler components that require superior mechanical properties. Industries such as consumer goods and industrial equipment often leverage these characteristics to meet specific product demands.

• Cost: The initial investment for die casting molds is higher due to their complexity, while permanent mold casting typically incurs lower costs over time due to the reusability of the molds. However, the choice between these methods should also take into account the long-term operational costs associated with production volume and part complexity.

How does permanent mold casting work?

The permanent mold casting process can be broken down into several key steps that define the precision and reliability of this non-expendable mold casting technique.

- Mold Preparation: The metal mold is cleaned and preheated to ensure optimal casting conditions. Preheating can also help reduce thermal shock that may lead to defects in the final product.

- Pouring: Molten aluminum is poured into the mold cavity, utilizing gravity for filling. This step requires careful control to avoid turbulence, which can introduce air pockets and imperfections in the casting.

- Cooling: The metal cools and solidifies within the mold, benefiting from the metal’s thermal conductivity. This controlled cooling process enhances the mechanical properties of the final product, resulting in a denser and more refined structure.

- Ejection: Once cooled, the mold is opened, and the finished part is ejected. The design of the mold plays an essential role in ensuring smooth ejection, minimizing the risk of damage to the part.

- Finishing: Additional machining or finishing processes may be applied to achieve the desired specifications. These processes may include surface treatments, polishing, or CNC machining to meet precise tolerances.

Materials Used

The molds are typically made from materials such as iron or steel, which provide durability and heat resistance. The choice of alloy for the casting is key, as it affects the final product’s strength and corrosion resistance. Procast employs advanced Solidification Analysis to ensure that the selected alloys are optimized for the specific application, minimizing defects and enhancing performance. The use of high-quality materials not only improves the lifespan of the molds but also contributes to the overall quality of the cast components.

Correctly assessing the unique qualities of individual Permanent Mold Casting Machine Manufacturers is vital in selecting the right equipment for optimal results. Procast’s in-house engineering capabilities ensure that each mold is designed to meet the precise specifications required for high-quality output, further enhancing the reliability of this non-expendable mold casting process. This commitment to quality is reflected in our rigorous testing and validation protocols.

Can I use mild steel to make a mold for casting aluminum?

Using mild steel for aluminum casting molds is generally not recommended due to several reasons:

-

Durability: Mild steel lacks the necessary strength and heat resistance when compared to other materials like iron or hardened steel. This can lead to deformation and reduced mold life, resulting in increased downtime and maintenance costs.

-

Casting Quality: The thermal properties of mild steel may not provide the optimal cooling rates needed for high-quality castings, potentially resulting in defects. Procast’s commitment to quality is reflected in our choice of robust materials for mold construction, ensuring that our molds withstand the rigors of repeated use while maintaining dimensional accuracy. Utilizing appropriate materials directly correlates with the quality and performance of the final products.

Metal Permanent Mold Casting Examples

For successful applications, consider using more robust materials for molds to ensure durability and casting quality. Industries such as medical equipment and defense often require stringent adherence to specifications, and Procast’s ISO 9001:2015 certification guarantees that our processes meet the highest standards of quality control. Our CNC Machining capabilities further facilitate the precise finishing of cast components, ensuring they meet the exact tolerances required for critical applications. This level of precision is essential for applications where safety and reliability are paramount.

Additionally, the integration of cutting-edge technology enhances the efficiency of the Permanent Mold Casting process. These systems enable real-time monitoring and management of production workflows, ensuring that every step from mold preparation to finishing is executed with precision and efficiency. By leveraging these technologies, Procast can optimize production schedules and improve overall operational effectiveness.

In summary, the choice between Permanent Mold Casting and die casting hinges on the specific requirements of the project, including design complexity, volume, and material properties. Understanding these differences empowers manufacturers to make informed decisions that align with their production goals and quality standards.

What is the lifespan of a die casting mold?

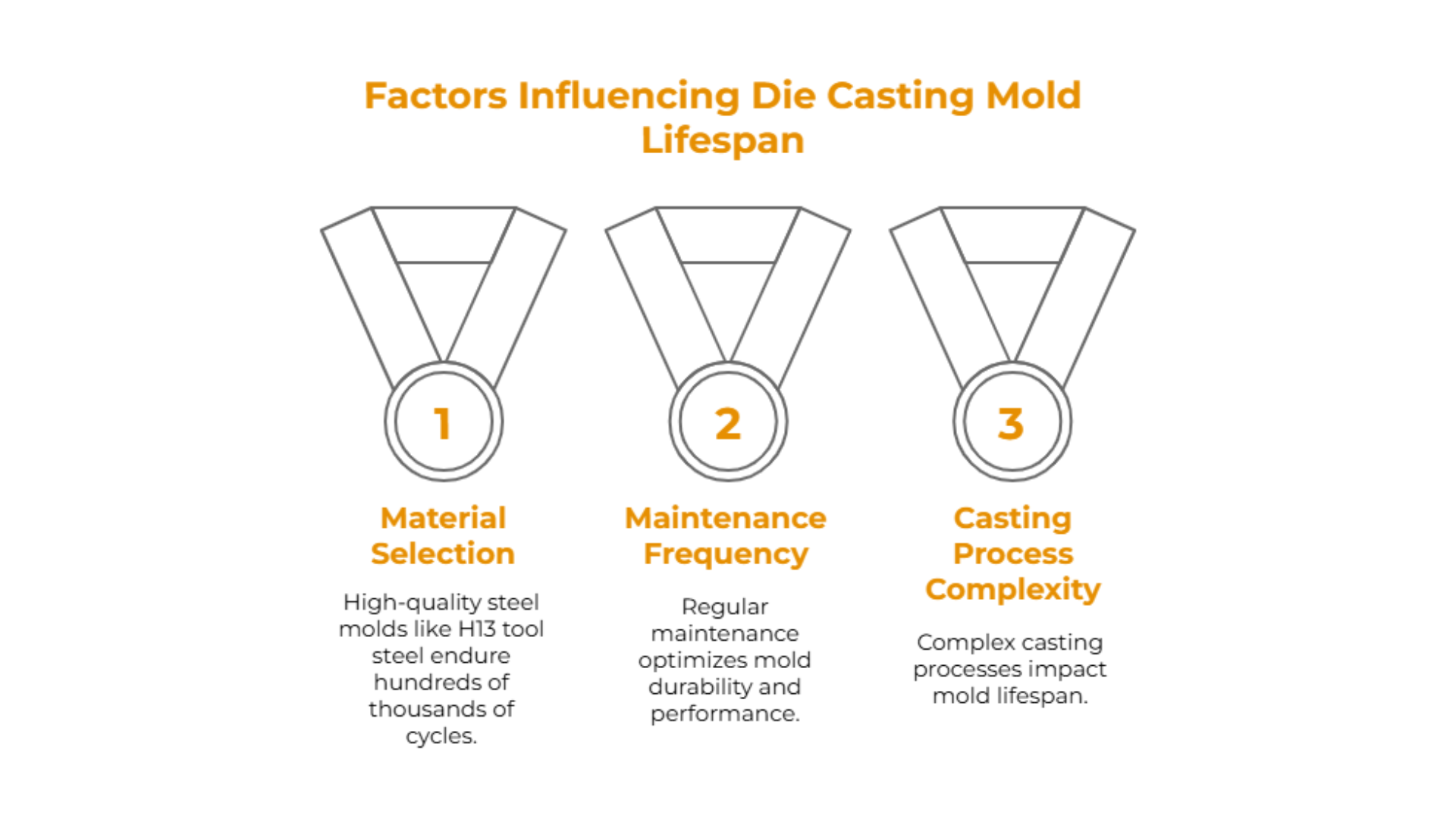

Understanding the factors that influence the lifespan of die casting molds is essential for manufacturers aiming to optimize production efficiency and cost-effectiveness. Recent advancements in materials, maintenance practices, and process optimization have significantly impacted mold durability and performance.

The lifespan of a die casting mold largely depends on factors such as material selection, maintenance frequency, and the complexity of the casting process. High-quality steel molds, such as those made from H13 tool steel, can endure hundreds of thousands of cycles due to their resistance to thermal fatigue and wear. In contrast, lower-grade materials reduce mold life and increase replacement frequency.

According to industry standards, the wear life of a permanent mold can range from 10,000 to 120,000 castings, depending on conditions and upkeep. Manufacturers analyzing permanent mold casting vs die casting cost must account for these variables, as mold longevity directly affects overall production expenses and efficiency. Choosing superior materials and implementing proper maintenance schedules can significantly extend mold life while maintaining consistent product quality.

What are the two basic methods for producing die castings?

Die casting typically employs two main processing methods: hot chamber and cold chamber. Both share the principle of forcing molten metal into a mold cavity under pressure, but they differ in how the molten metal is delivered to the mold.

The hot chamber method is ideal for metals with low melting points, such as zinc and magnesium. It uses a built-in furnace that keeps the metal in a molten state, allowing rapid cycling and high production efficiency. The cold chamber method, contrastingly, is used for metals with higher melting points like aluminum and brass. Here, molten metal is ladled into a separate chamber before being injected into the die under high pressure.

When evaluating permanent mold casting vs die casting pros and cons, die casting offers faster production rates and good dimensional accuracy, making it ideal for high-volume manufacturing. Permanent mold casting, however, provides superior mechanical properties and a smoother surface finish due to slower cooling rates, which can be more suitable for medium-volume production or parts requiring enhanced durability.

How to make permanent mold casting

Creating a permanent mold involves several carefully controlled steps to ensure consistency and quality. The process begins with mold preparation, where the metal mold is cleaned and preheated to prevent thermal shock. Next comes the pouring phase, where molten aluminum is poured into the cavity using gravity rather than pressure.

The cooling stage allows the metal to solidify within the mold, improving its density and mechanical strength. Once cooled, the part is ejected and may undergo additional finishing, such as machining or polishing, to achieve the desired tolerances.

To optimize results, manufacturers often use solidification analysis and computer-aided simulation tools to predict how the molten metal will behave inside the mold. This proactive approach helps prevent defects such as shrinkage, porosity, or cold shuts, resulting in components with superior structural integrity. Proper venting and gating design also play an essential role in ensuring smooth metal flow and uniform cooling, both of which directly influence surface finish and dimensional accuracy.

In comparing permanent mold casting vs die casting, the key distinction lies in pressure: die casting uses high-pressure injection, while permanent mold casting relies on gravity. This difference impacts part strength, surface finish, and overall cost-efficiency. Permanent molds—made from iron or steel—are reusable, offering a cost-effective solution for medium to high production volumes while maintaining excellent consistency and dimensional stability. Furthermore, their ability to be coated or treated with refractory materials extends mold life, minimizes sticking, and ensures repeatable, high-quality results across thousands of cycles.

Which of the following casting processes is a permanent mold operation?

A permanent mold operation refers to any casting process that employs a reusable metal mold, generally made from iron or steel, capable of withstanding repeated thermal cycles. Unlike expendable molds, which are destroyed after each pour, permanent molds are designed for longevity and consistency, making them ideal for medium to high-volume production runs where dimensional accuracy and mechanical strength are priorities.

Among the most common types are gravity permanent mold casting and low-pressure permanent mold casting. In gravity casting, molten aluminum flows naturally into the mold under the force of gravity, producing parts with excellent density and fine surface finish. The low-pressure variation introduces controlled gas pressure to feed the molten metal upward into the cavity, allowing even greater control over filling, cooling, and solidification. These techniques enhance the metallurgical structure of the casting, resulting in superior strength and reduced porosity—qualities highly valued in the automotive and aerospace industries.

In contrast, sand casting employs expendable molds made from sand and binders, which must be rebuilt for every casting cycle. While this provides greater flexibility for complex or oversized geometries, it cannot rival the consistency, efficiency, and refined surface finish offered by permanent mold operations. Manufacturers evaluating production methods must consider volume, precision, and performance requirements when determining whether a permanent mold process is the most suitable solution for their application.

For more information on Permanent Mold Aluminum Casting, including benefits, techniques, and innovations, visit our website, Procast. Don’t hesitate to reach out for personalized advice on selecting the best casting method for your specific project.

Our team of experts is here to guide you through every step, ensuring you achieve the highest quality results while maximizing efficiency and cost-effectiveness.