Permanent mold casting is a manufacturing process utilized across numerous industries. This essential technique relies on reusable metallic molds to efficiently produce components of high quality and inherent precision. It is of particular value when working specifically with nonferrous alloys, such as aluminum.

Permanent mold casting offers superior control over solidification, especially when compared to alternatives like sand casting.. Its precise control mechanisms result in finished parts with improved mechanical properties and notably enhanced surface finishes. It further facilitates the efficient realization of complex designs, offering an economical and reliable manufacturing process that meets rigorous engineering standards.

For manufacturers aiming to achieve long-term structural integrity and consistency in their products, an understanding of the multifaceted benefits of permanent mold aluminum casting is absolutely essential for strategic success.

The following discussion explores in depth the specifics of the permanent mold process. It details its diverse, real-world permanent mold casting applications, carefully evaluates the differences between the various competing casting types, and thoroughly addresses the core cost concerns associated with implementing this highly versatile production method.

What is the process of permanent mold casting?

The methodology of permanent mold casting centers on introducing molten metal into a carefully constructed mold. In most permanent mold casting applications, the molten alloy is introduced into a casting cavity, usually via a gravity feed mechanism.

The mold itself is constructed from highly durable materials like iron or steel. Importantly, the mold is specifically engineered for repeated use across a vast number of production cycles. The entire production technique is defined by its reliance on non-expendable tooling. This specialized tooling is precisely engineered to achieve high component consistency and precision across every single production cycle.

The core physical mechanism deployed relies heavily on controlled solidification. During this phase, the molten aluminum alloy experiences rapid cooling due to its direct and immediate contact with the metallic walls of the mold. This highly accelerated heat extraction actively promotes the formation of a finer, more uniform grain structure within the solidified alloy. Known as grain refinement, this critical metallurgical phenomenon is recognized as the direct catalyst contributing to the enhanced strength and ductility achieved in the finished component.

The final physical properties realized in the cast parts are intricately linked to a complex interplay of variables. These include the specific alloy’s composition, the precise setting of the crystallization parameters, and the application of any post-casting thermal processes. A primary goal is to minimize any local differences in crystallization parameters. This is vital to ensuring a truly uniform material structure is consistently present throughout the entire part.

Parts successfully produced via permanent mold casting are designed to accommodate a wide range in size, ranging from just a few ounces to over one hundred pounds. The permanent mold process is further capable of precise dimensional control, with linear tolerances frequently achievable within a tight, specific range of 0.010″ to 0.025″ in practice.

Other permanent mold casting examples include a variant known as semi-permanent mold casting. This specialized approach skillfully integrates expendable sand cores into the reusable metallic mold structure. These are utilized to form complex internal geometries or intricate features such as internal pathways or undercuts, none of which can be successfully achieved using standard metallic tooling alone. This capacity can be absolutely critical for highly specialized components, such as highly stressed engine parts or intricate valve bodies.

Permanent mold casting Vs. Die Casting?

A comparison of permanent mold casting vs die casting price reveals that the optimal choice between the two is dictated by total production volume and the structural integrity requirements of the component. Die casting involves forcing molten metal into tooling under high pressure, enabling fast cycle times and very tight tolerances, but it restricts component size and internal feature complexity.

Tooling and Setup:

Die-cast tooling is complex and exceptionally expensive, making the method only economically viable for consistently high production volumes where the massive tooling cost is amortized across millions of parts. Permanent mold tooling, while still a substantial capital investment, generally has a lower upfront cost, making it the preferred method.

Structural Integrity:

Beyond cost, the quality of the final part is paramount. Die casting’s high-pressure injection method creates a risk of internal gas porosity or trapped air. Static or tilt pour permanent mold casting, however, promotes directional solidification, resulting in a meaningfully denser, more uniform microstructure with minimal internal defects. This focus on material soundness affects the overall value proposition.

When evaluating whether cast aluminum is suitable for critical components, structural reliability becomes the defining factor. Permanent mold casting reliably delivers the consistent quality needed to meet such stringent mechanical standards, often providing superior value over high-speed die casting for highly structural components – despite potentially higher per-unit costs at the highest volumes.

What are some examples of industries that can utilize permanent mold castings?

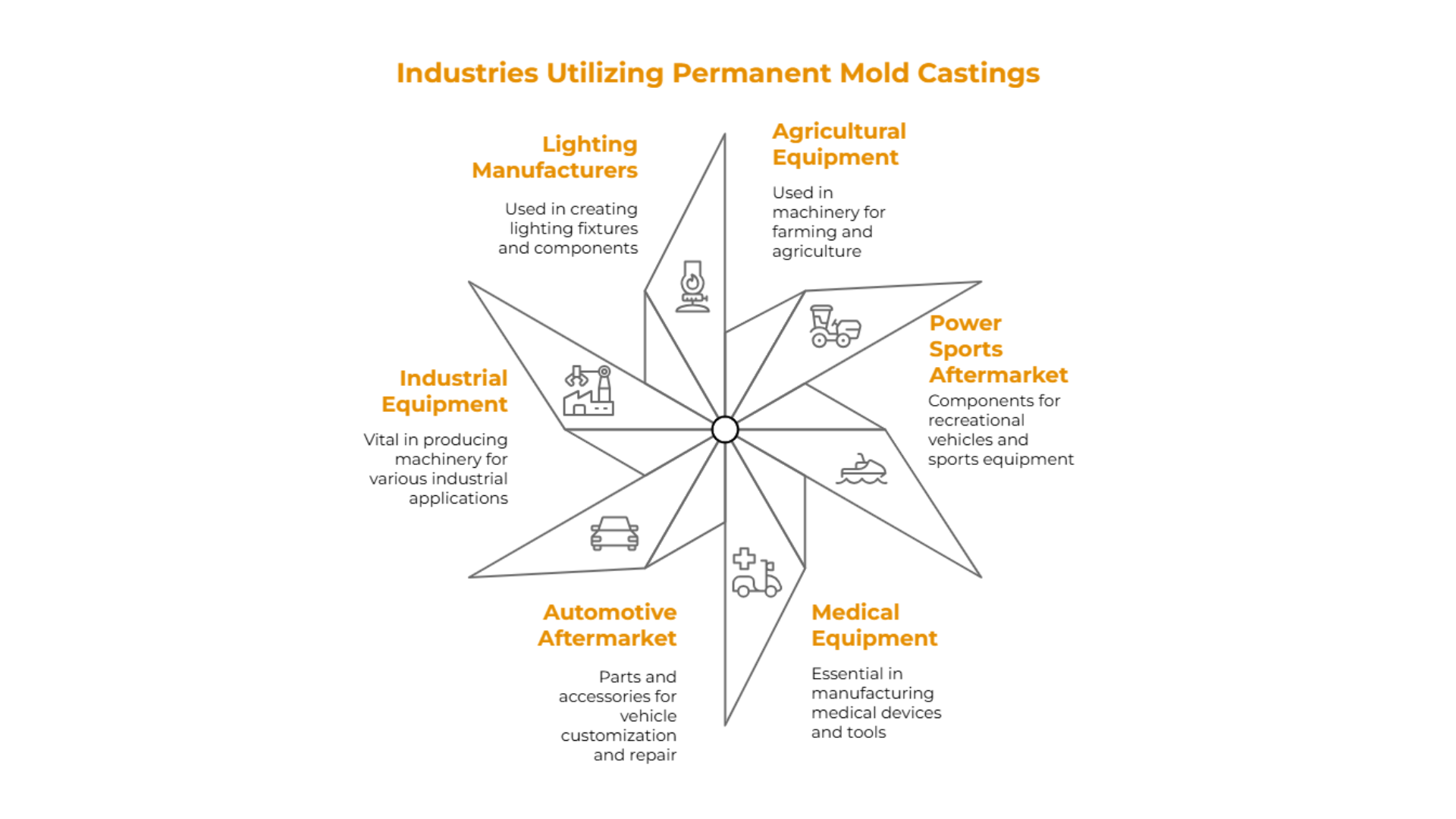

Permanent mold casting is implemented across various critical industrial sectors, usually in situations where product reliability and structural integrity are high-priority requirements. The capability for permanent mold casting aluminum using distinct types of permanent mold casting techniques (such as tilt-pour or static pour) is typically utilized for high-performance medium-to-high volumes of components. The versatility and the stringent quality control inherent in this method allow it to consistently meet demanding specifications across numerous key markets.

Permanent mold casting is very important in the automotive aftermarket, producing highly stressed parts like transmission housings, cylinder heads, and pistons that require high structural density and durability under extreme thermal and mechanical conditions. Similarly, the industrial equipment sector uses these castings for robust machinery housings and durable functional components where maintaining high dimensional accuracy during continuous operation is mandatory.

Lighting manufacturers utilize the process for fixtures that demand an optimal surface finish for aesthetics and precise thermal management. Their superior surface finish and tight tolerances minimize secondary operations.

The process also serves several specialized markets:

- →Agricultural equipment requires large, strong, and highly durable components.

- →The power sports aftermarket demands lightweight yet high-strength parts to optimize the strength-to-weight ratio.

- →Medical equipment specifies components that must adhere to rigorous purity and tight dimensional accuracy standards for structural and aesthetic applications.

These applications underscore the ability of permanent mold casting to produce highly consistent, structurally dense pieces with precision craftsmanship.

| Industry Sector | Typical Components | Key Benefit from Permanent Mold |

|---|---|---|

| Automotive Aftermarket | Transmission housings, engine parts, structural parts | High structural density and reliability |

| Industrial Equipment | Housings, durable brackets, compressor parts | Consistency and resistance to stress, and pressure tightness |

| Lighting Manufacturers | Fixtures, thermal management parts, structural parts | Superior surface finish, thermal stability |

| Medical Equipment | Precision components, structural parts, housings | High purity and integrity requirements |

What is the difference between a die and a mold?

The distinction between a mold and a die is defined by the application of force during metal forming. A mold, particularly in permanent mold casting, is a durable, rigid metallic tool, often fabricated from materials like steel or iron, designed for gravity or low-pressure pouring. This durability makes the process inherently consistent and cost-efficient. A successful aluminum casting foundry uses these steel molds, offering an economical and high-quality alternative to pressure die casting.

The utilization of steel permanent molds introduces a key difference in solidification kinetics, rapidly extracting heat from the molten aluminum to accelerate cooling. This rapid solidification refines the alloy’s grain structure, directly enhancing its mechanical properties, including increased tensile strength. Consequently, permanent mold components achieve superior surface finishes and much tighter dimensional tolerances, ensuring exceptional quality and consistency for custom aluminum castings.

In contrast, a die refers to specialized tooling engineered for processes requiring intense force, such as high-pressure die casting. Dies used in high-pressure methods contrast sharply with the non-pressurized permanent mold method. For example, due to the need to withstand very large forces, extrusion dies are generally crafted from high-strength steels like H11 and H13, with their surfaces hardened through nitriding. Ultimately, the difference hinges on the application: steel permanent molds determine solidification kinetics via heat extraction, while dies manage metal flow under intense pressure.

How much does aluminum casting cost?

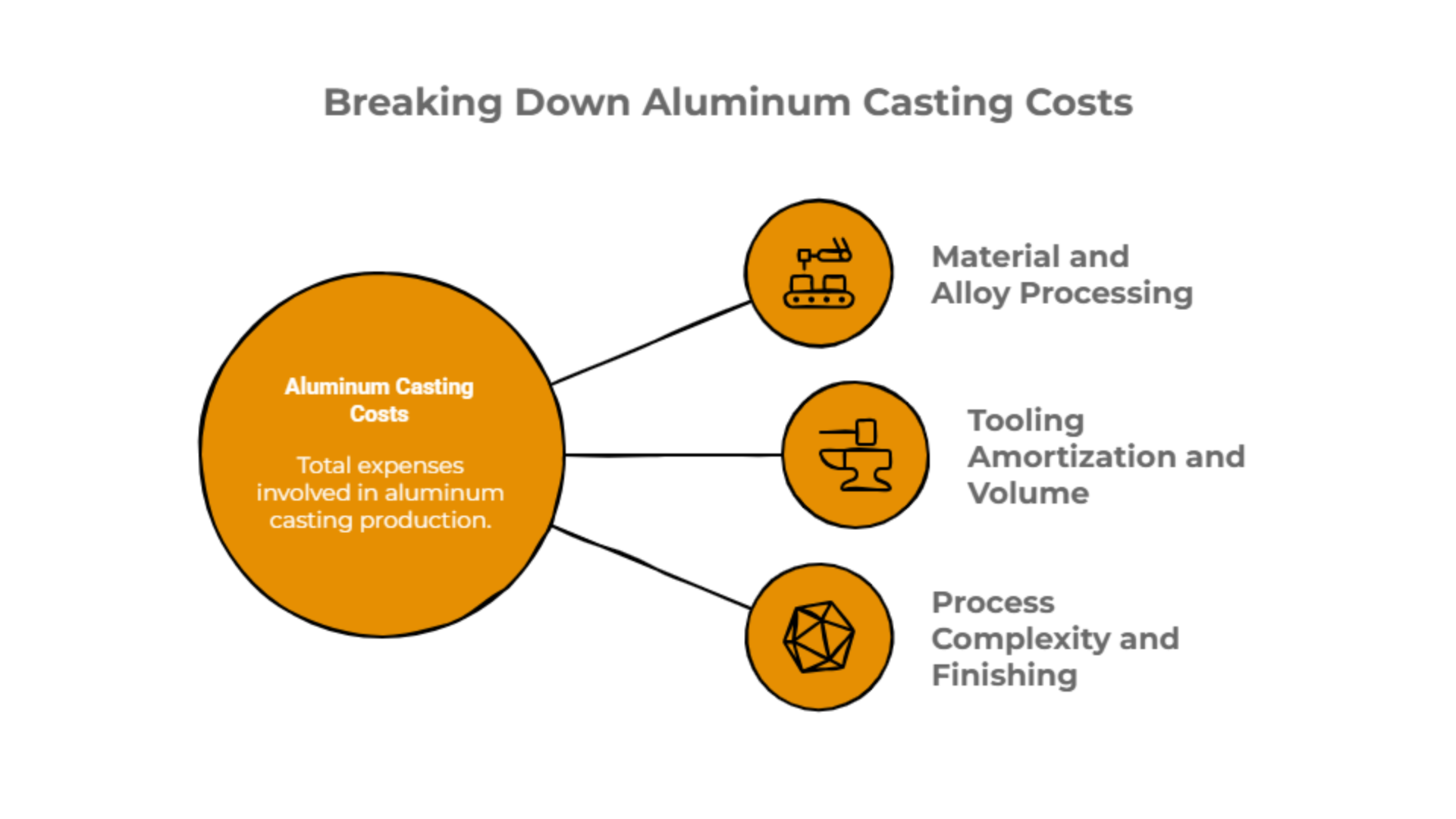

An assessment of how much it costs to cast aluminum depends on a complex interplay of material selection, process efficiency, component geometry, and required finishing treatments. These variables are then calculated against the expected quality and volume. Understanding the permanent mold casting vs die casting price balance is also essential, as tooling costs, production volumes, and achievable tolerances can vary meaningfully between the two methods.

Factors influencing the total cost include:

- Material and Alloy Processing: The aluminum alloy composition is a core cost driver. Specialized, high-performance alloys inherently carry a higher material cost. Also, alloys selected for high yield and tensile strengths are generally harder to process, resulting in lower production rates in forming operations. This correlation between desired mechanical properties and processing difficulty increases complexity and cost in casting as well.

- Tooling Amortization and Volume: The permanent mold process requires the production volume to be substantial enough (500 to 50,000 pieces annually) to efficiently absorb the initial tooling investment. To achieve a cost-efficient process in an aluminum casting factory, the total lifetime output must justify the mold construction and maintenance.

- Process Complexity and Finishing: Incorporating sand cores in the semi-permanent mold technique for complex internal geometries adds to production costs. While a permanent mold reduces the need for initial cleanup, achieving ultra-tight linear tolerances beyond the standard tolerance range often necessitates secondary CNC machining operations, which add labor, time, and expense to the final price.

The final determination of economic feasibility requires a precise understanding of the balance between manufacturing capability and the component’s functional requirements.

What are the disadvantages of cast aluminum?

Choosing the right aluminum casting foundry is a critical strategic decision that requires partnering with a supplier capable of providing a comprehensive, single-source quality driven solution. This partnership should go beyond just metal pouring to include detailed engineering support, solidification analysis, stringent quality control, and reliable delivery.

A specialized aluminum casting factory offers essential services that start with engineering design support, which optimizes component design before tooling is manufactured. Operational capabilities must integrate casting with necessary secondary processes like heat treatment and precision machining. Given the precision required, a reliable foundry adheres to strict internal quality control procedures to manage the entire manufacturing process, from raw material inspection to final component certification.

Does casting aluminum present value?

The commitment to consistently deliver a dense, quality product reinforces the component’s value, linking the aluminum casting foundry’s expertise directly to the product’s ultimate performance. The best foundries emphasize core competencies: precision craftsmanship ensures high dimensional accuracy, reliability ensures on-time delivery, and continuous technological investment helps maintain process control.

Conclusion

The world of permanent mold aluminum casting offers unparalleled opportunities for manufacturers seeking precision and reliability in their medium-to-high volume production. By controlling solidification and utilizing durable metallic tooling, this process consistently delivers superior structural integrity when compared to alternatives like sand casting, while offering a notably denser, more uniform microstructure than die casting for critical applications.

Ready to dive deeper into the world of Permanent Mold Aluminum Casting here at Procast Technologies? Explore our comprehensive resources and expert insights to enhance your understanding and application of this innovative process. Join our community today and unlock the potential of your projects!