What are the Advantages and Disadvantages of the Permanent Mold Process?

December 12, 2025

In the world of manufacturing, choosing the right casting method is crucial for achieving precision and quality, with both its advantages and disadvantages playing key roles in the decision-making process. This article delves into the benefits and drawbacks of permanent mold casting, providing insights to help manufacturers optimize their production processes. It will facilitate more informed choices to align your project requirements with industry standards. (For a comprehensive overview, visit our Permanent Mold Aluminum Casting pillar page)

What is the Basic Permanent Mold Process?

The permanent mold process involves several key steps that differentiate it from other casting methods, using durable, reusable metal molds that ensure high precision and long-term consistency.

Key Steps in the Permanent Mold Process:

- Mold Preparation: The mold is cleaned, preheated, and sprayed with refractory coatings to ensure proper metal flow and minimize defects.

- Metal Pouring: Molten metal is poured into the mold cavity, allowing it to cool and solidify.

- Casting Removal: Once the metal has cooled sufficiently, the mold is opened to remove the cast part.

Unlike expendable mold processes where molds are destroyed after a single use, permanent molds can be used repeatedly, leading to cost savings and consistent quality over time. This makes permanent mold casting applications for metal particularly advantageous in high-volume production scenarios. Additionally, Procast employs advanced simulation techniques such as Solidification Analysis to mitigate defects before production, further enhancing the reliability of the casting process.

What Materials are Used for Permanent Mold?

The materials used in permanent mold casting are critical to the process’s success. Common materials include:

- → Aluminum Alloys: Lightweight and excellent for thermal conductivity.

- → Zinc Alloys: Known for their corrosion resistance and strength.

- → Copper Alloys: Offer superior durability and thermal properties.

These casting metals are chosen for their ability to endure high temperatures and repeated casting cycles, making them ideal for permanent molds.

These materials are chosen for their ability to endure high temperatures and repeated casting cycles, making them ideal for permanent molds. Understanding the advantages and disadvantages of casting with these materials is essential for optimizing production efficiency. Procast’s commitment to ISO 9001:2015-certified quality ensures that all materials meet stringent industry standards, further enhancing the reliability of the final product.

What are the Three Basic Steps in Casting?

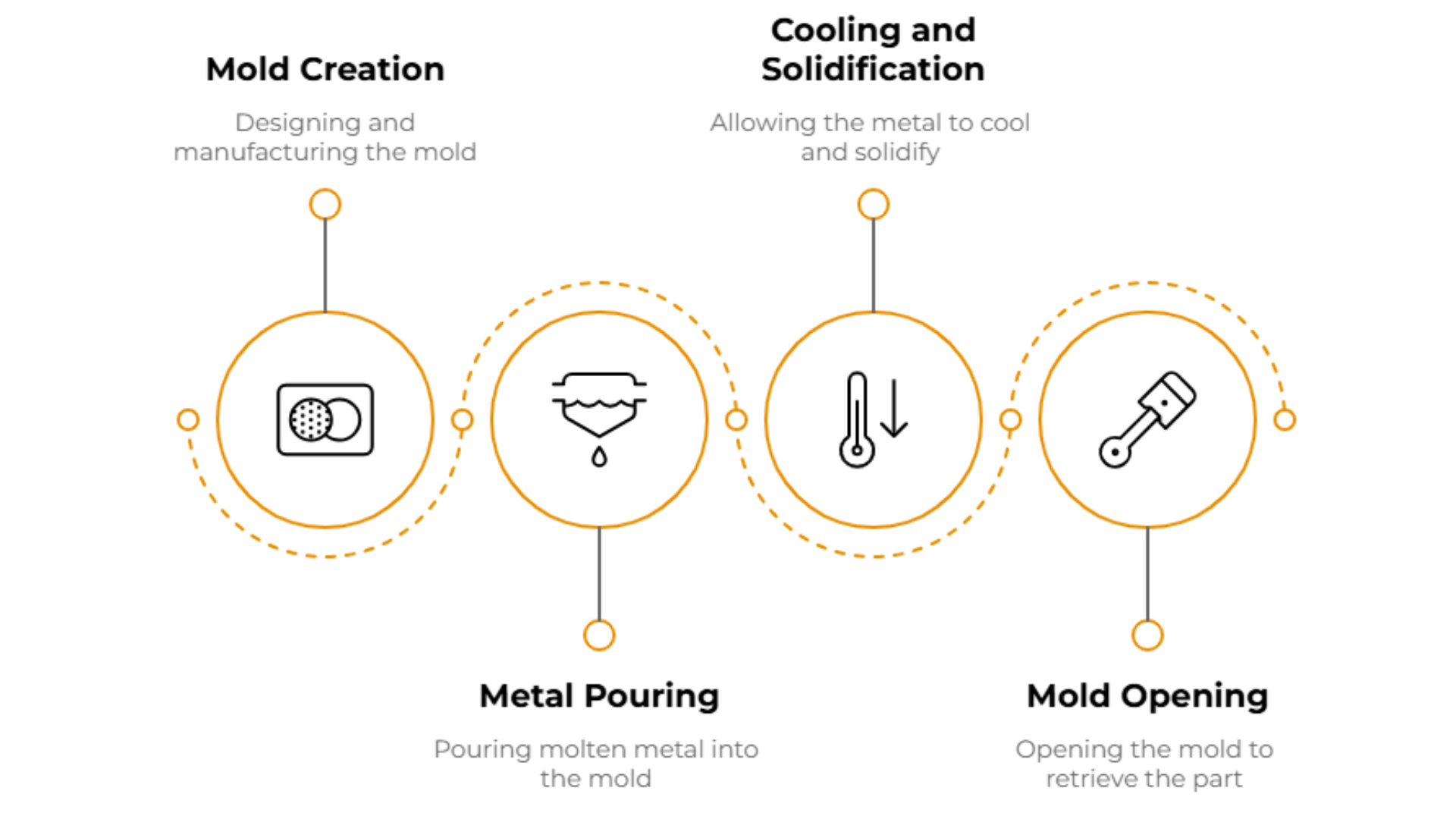

The three fundamental steps involved in the Permanent Mold casting process are:

- Mold Creation: Involves designing and manufacturing the mold, ensuring it meets the specifications for the desired part.

- Metal Pouring: The molten metal is poured into the prepared mold, filling the cavity to form the desired shape.

- Cooling and Solidification: The metal is allowed to cool and solidify, after which the mold is opened to retrieve the finished part.

These steps are crucial for ensuring that the final product meets stringent quality standards. Advanced techniques such as Solidification Analysis further enhance the quality of the cast parts. Procast’s in-house engineering, CNC machining capabilities, and Quality System, provide additional layers of precision and control throughout the entire process.

What is the Difference Between Expendable and Permanent Molds?

Expendable Molds: |

Permanent Molds: |

|---|---|

|

Definition: Molds that are destroyed after a single use. Advantages: ✓Flexibility in design for complex geometries. ✓Lower initial investment. Disadvantages: ✗Higher per-part cost due to the need for new molds. ✗Potential for variability in quality. |

Definition: Reusable molds that can produce multiple parts. Advantages: ✓Cost-effective for high-volume production. ✓Consistent quality and precision across high volume production runs.. Disadvantages: ✗Higher initial setup costs. ✗Limited design flexibility compared to expendable molds. |

A firm understanding of the differences between these two types of molds helps manufacturers decide which process best aligns with their production goals. The choice typically depends on factors such as production volume, part complexity, and budget considerations. Procast’s custom inventory management solutions further alleviate the burden on clients by optimizing their in-house stock levels, making permanent mold casting an even more attractive option for high-volume needs.

Conclusion

If you’re considering the permanent mold casting process for your next project, we invite you to reach out for a consultation. Our team at Procast Technologies is dedicated to providing top-tier custom aluminum casting and machining solutions tailored to your unique project needs.

Let’s work together to elevate your manufacturing capabilities. For more information, please visit our contact page.