Is sand casting better than permanent mold casting?

December 12, 2025

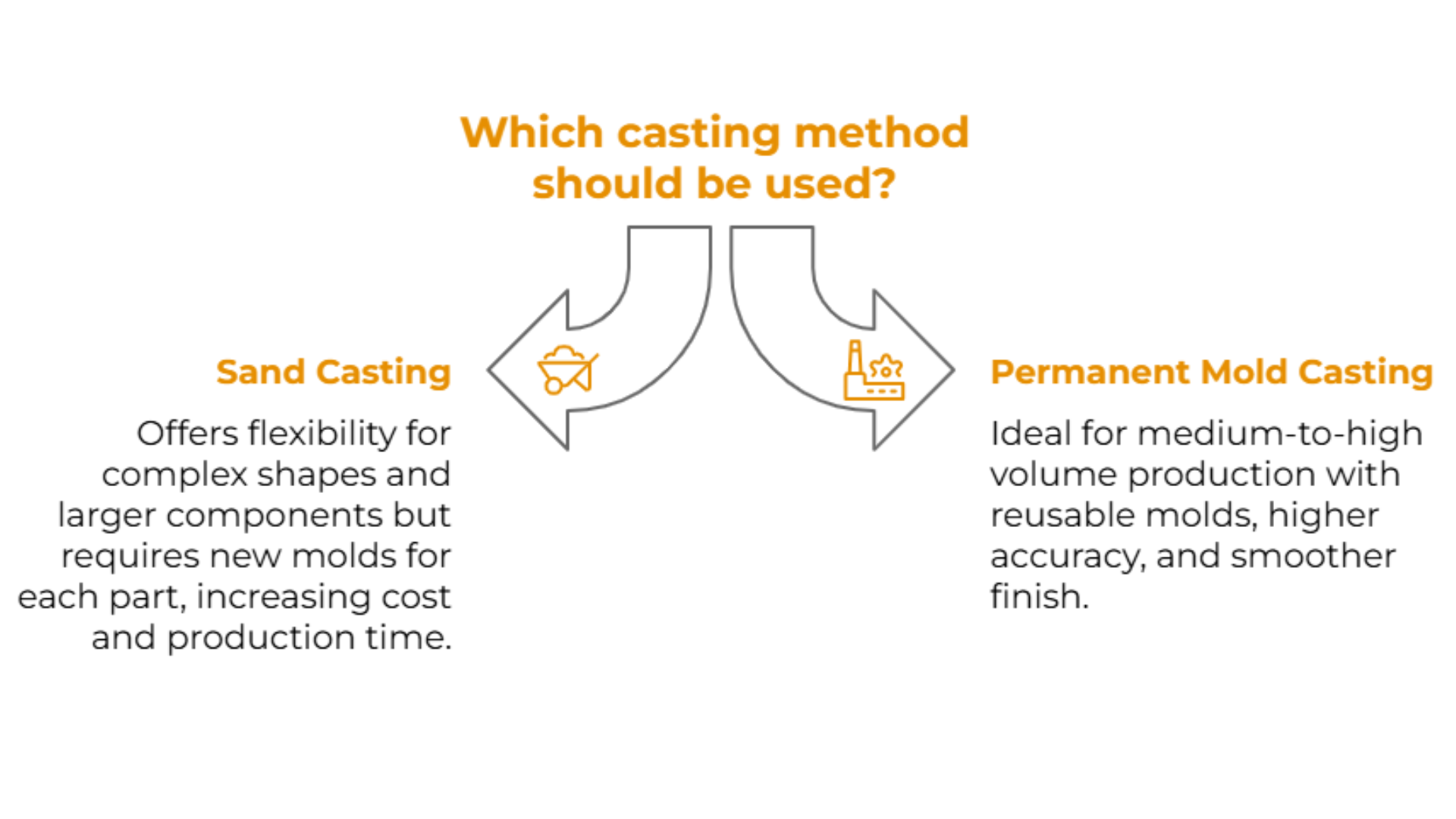

The choice between sand casting and permanent mold casting is a key decision when evaluating manufacturing methods for metal components. Factors such as production volume, part complexity, and budget all deserve careful consideration. These decisions are essential for optimizing both quality and cost efficiency, whether you’re exploring Permanent mold casting advantages and disadvantages or looking for detailed insights into Permanent Mold Aluminum Casting. In this article, we’ll explore these topics in depth to help you determine which casting method best fits your manufacturing needs.

What is the permanent mold casting process?

The permanent mold casting process involves pouring molten metal, typically aluminum, into durable molds. These molds are designed for reusability, making this process ideal for medium-to-high volume production runs. Gravity or low pressure is used to feed the metal, delivering castings with improved dimensional accuracy and superior surface finish when compared to sand casting. Another key advantage is that the molds can be reused thousands of times, ensuring consistent output for large production runs.

This process is commonly used in industries that require precision, high-performance parts, such as the aerospace and automotive sectors. With production volumes ideally ranging from 500 to 50,000 pieces annually, permanent mold casting is both cost-effective and efficient, providing high-quality results for large-scale manufacturing.

Key Features of Permanent Mold Casting

- Production Volume: Ideal for 500 to 50,000 pieces annually.

- Mold Reusability: Molds can be used thousands of times.

- Quality: Superior dimensional accuracy and smooth surface finish.

What are the different casting types?

There are several types of sand casting and permanent mold casting methods, each with its own advantages and disadvantages depending on project needs. Sand casting is a popular expendable mold casting technique that uses a sand mixture to create molds that are destroyed after each use. This method allows for flexibility in producing complex shapes and larger components, which may be difficult to achieve with permanent molds. However, the downside of sand casting is that each part requires a new mold, which can increase the cost and production time for larger runs.

On the other hand, permanent mold casting uses durable, reusable molds, which are ideal for medium-to-high volume production. The molds can be used thousands of times, making it more efficient for mass production. Unlike sand casting, which tends to have rougher surface finishes and less dimensional precision, permanent mold casting produces parts with higher accuracy and a smoother finish.

A typical sand casting application is used in aluminum sand casting foundries, where molds are created for the production of aluminum parts that require a complex design. This method is cost-effective for lower production volumes but may not meet the quality demands of high-performance industries. In contrast, permanent mold casting is more suitable for industries requiring consistent quality and precision, such as aerospace and automotive manufacturing.

Sand Casting

|

Permanent Mold Casting

|

Is sand casting an expendable mold?

Yes, sand casting is an expendable mold process. Molds are created using a sand mixture, which is combined with a binder to form the shape of the desired part. Once the molten metal is poured into the mold and allowed to solidify, the mold is destroyed to release the part. This is the essence of the expendable mold concept, whereas in the case of permanent mold casting, molds can be reused multiple times.

The use of expendable molds in sand casting meaningfully affects the production process. Since a new mold is required for every part, sand casting can be more time-consuming and expensive for high-volume production runs. However, it is well-suited for producing intricate or complex designs that might not be possible with permanent molds. This flexibility in design is a major advantage, but the need to create new molds for each part increases material usage and overall cost for larger quantities.

In contrast, permanent mold casting offers the advantage of mold reusability, which reduces material waste and overall production costs for medium-to-high volume runs. The ability to reuse molds thousands of times leads to improved cost efficiency and consistency in output, making it ideal for projects where precision and repeated quality are critical.

Is sand casting low-cost?

Sand casting is often considered an economical method, especially when compared to permanent mold casting. The initial setup for sand casting is relatively inexpensive, as it primarily involves creating molds from sand mixed with a binder. This makes it a great choice for low-volume production or prototype runs, where expensive tooling isn’t necessary.

So, is sand casting low-cost? Yes, typically, but its cost-effectiveness diminishes as production volumes increase. Since a new mold is required for each part, material costs and labor associated with creating the molds rise with volume. Additionally, parts may require extensive secondary finishing to improve surface quality. In contrast, permanent mold casting requires a larger initial investment in durable molds, but the cost-per-unit decreases considerably as production increases, making it more economical for medium-to-high volume manufacturing.

Is sand casting better than permanent mold casting for metal?

The specific needs of the project most often determine whether sand casting or permanent mold casting is better for metal. In terms of performance and quality, permanent mold casting generally delivers superior results. It produces castings with better dimensional accuracy, smoother surface finishes, and greater consistency, especially beneficial for high-performance industries like aerospace and automotive.

However, there are situations where sand casting may be the better option. For instance, when producing large, complex, or irregularly shaped parts, sand casting provides more flexibility with the ability to create intricate internal features. This makes sand casting ideal for low-volume runs or custom parts that require designs not easily achievable with permanent molds.

For projects that involve small quantities, custom parts, or complex designs, sand casting is often the more affordable option, offering flexibility without the need for significant upfront investment.

Which one of the following casting processes is the most widely used?

Sand casting remains the most widely used casting process globally, largely due to its versatility, low initial setup costs, and ability to handle various metals and part sizes. Industry reports indicate that sand casting accounts for over 70% of casting operations worldwide. This makes it a go-to method for many manufacturers, especially for low-volume production runs.

However, permanent mold casting is increasingly gaining traction in industries that demand higher precision, such as automotive and aerospace. Trends show a growing need for high-quality, precise components driving this rise. Factors such as cost, complexity, and production volume will continue to influence the choice of casting methods in modern manufacturing.

Want to learn more about permanent mold aluminum casting at Procast Technologies? Subscribe to our blog for in-depth articles, industry trends, and expert tips to enhance your casting processes. Stay ahead in the field—join our community today!