What is the difference between Pressure die-casting and permanent mold?

December 12, 2025

In the manufacturing world, particularly for producing metal parts with repeatable precision, permanent mold casting and die casting are two highly utilized techniques. While both methods employ durable, reusable molds (dies), they are fundamentally distinguished by the mechanism used to introduce the molten metal into the mold cavity.

Permanent mold casting relies on gravity (or tilting) to fill the mold, whereas die casting uses substantial pressure for injection. Understanding this core difference, alongside variations in economic considerations, materials, and resulting quality, is essential for selecting the appropriate process for a specific application.

Permanent Mold Casting (Gravity Die Casting)

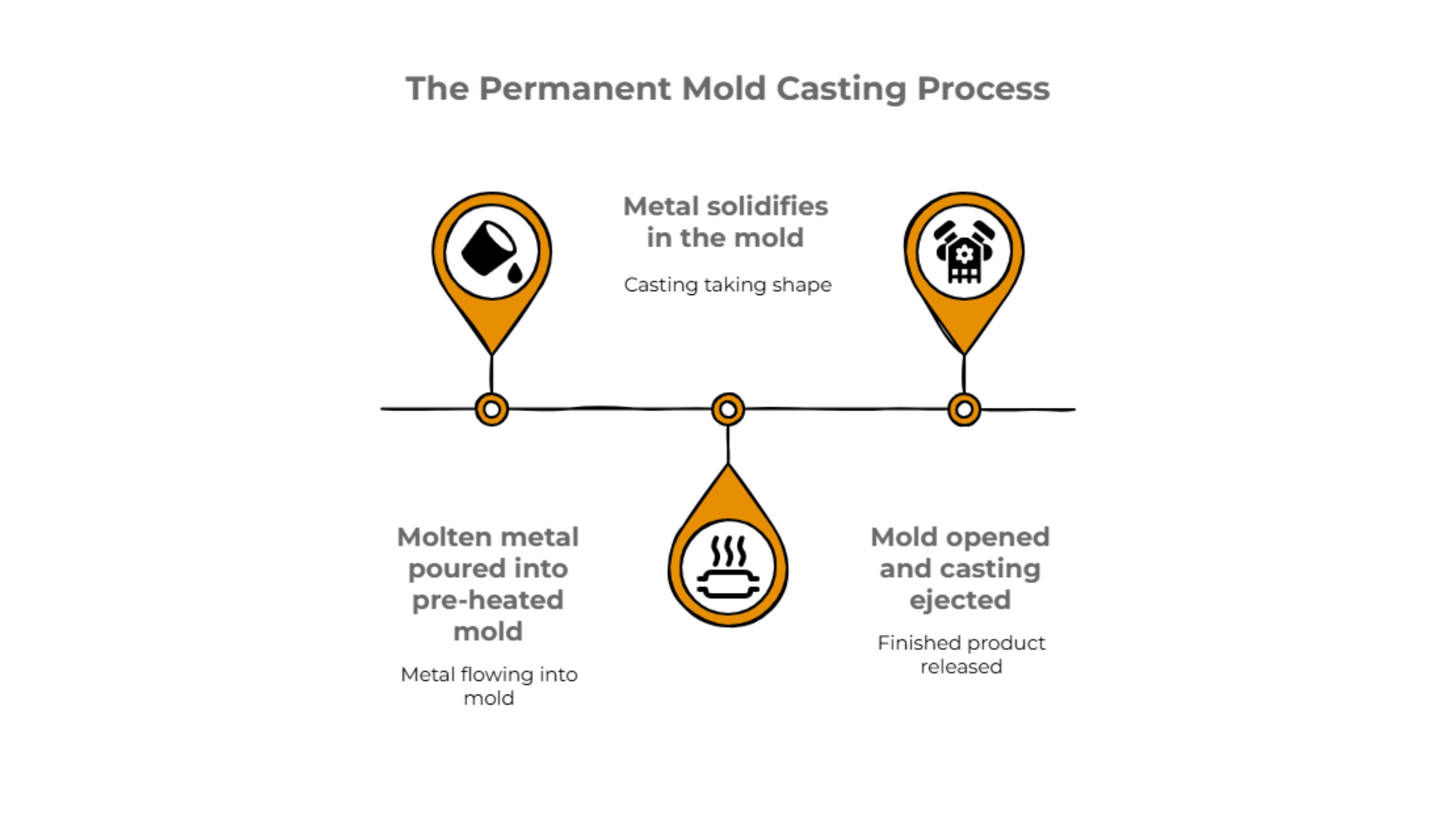

Permanent mold casting is often referred to as gravity die casting. In this process, molten metal is poured under gravity into a pre-heated die. The die is opened, and the casting is ejected once the metal solidifies. To reduce turbulence while pouring the molten metal, large castings sometimes require the mold to be tilted.

Process and Materials

The dies used in this method are typically constructed from cast iron, graphite, or tool steels. Non-ferrous metals are commonly used, such as aluminum, copper, magnesium, lead, tin, and zinc alloys. Carbon steel can also be cast using graphite dies.

A variation known as low-pressure die casting is less popular than gravity die casting but exists; it uses low-pressure air (around 1 bar) to force the molten metal into the die cavity, often employed for producing car wheels.

Economic and Quality Aspects

The permanent mold process is considered an economical and high-quality alternative to pressure die casting. It is typically suitable for medium production volumes, ranging from 500 to 50,000 pieces annually, ensuring efficiency and cost-effectiveness. Production rates generally fall between 5 and 50 castings per hour, dependent on the size of the part. However, the Permanent Mold Process initial tooling costs are usually 1/10th the costs of Pressure Die Casting giving it the advantage in most medium production requirements.

In terms of quality, permanent mold castings offer:

•Good surface detail.

•Surface roughness in the range of 0.8–6.3 µm.

•Mechanical properties that are fair to good.

•Dimensional allowances (tolerances) for dimensions across the parting line typically range from 0.010” to 0.025”.

•Superior surface finishes, dimensional accuracy, and strength-to-weight ratios compared to pressure die casting.

For complex internal shapes that pressure die casting cannot achieve, the semi-permanent mold process utilizes sand cores within the permanent mold. Permanent mold casting also handles a good range of sizes, from ounces up to 100 lbs.

Pressure Die Casting

Pressure die casting is defined by the injection of molten metal into a metallic mold under very high pressures (exceeding 100 bar). Once solidified, the die is opened, and the casting is ejected.

Process Variations and Materials

The tooling for this high-pressure process consists of dies made from hardened and tempered alloy steel. There are two main operational variants:

- Cold-chamber die casting: The shot cylinder is filled with a ladle for each cycle and is used for metals requiring high melting temperatures.

- Hot-chamber die casting: The shot cylinder is immersed in the molten metal, and a separate ram forces the metal into the cavity. This process is used for low-melting temperature metals.

Materials used are limited to non-ferrous metals, primarily zinc, aluminum, magnesium, lead, tin, and copper alloys. Zinc and aluminum alloys are the most popular choices.

Economic and Quality Aspects

Pressure die casting is characterized by its capability for very high production rates, potentially up to 200 parts per hour. It is highly economical for large production volumes, particularly 100,000+ units for aluminum, zinc, and lead alloys. Full automation, often involving robotic machine loading and unloading, is achievable.

In terms of product quality and design:

•Excellent surface finish is achieved.

•Surface roughness typically falls in a tighter range of 0.4–3.2 µm.

•Achievable dimensional tolerances across the parting line can be as tight as ±0.05 to ±0.35 mm.

•Mechanical properties are fair, but generally poorer than those achieved by some other casting methods.

•While shape complexity can be high, it is often limited by the design requirements of movable cores.

•The high pressure aids metal flow, permitting smaller radii. Minimum section thicknesses can be as small as 0.4 mm for zinc alloys.

•Low porosity is characteristic of small castings, but achieving quality in thick or long sections may be challenging due to potential porosity issues.

Summary of Key Differences

| Feature | Permanent Mold Casting (Gravity Die Casting) | Pressure Die Casting |

|---|---|---|

| Filling Method | Uses gravity to pour or tilt molten metal. | Uses very high pressure (100+ bar) to inject molten metal. |

| Typical Volume | Medium volumes (500 to 50,000 pieces). | Very high volumes (100,000+ pieces for popular alloys). |

| Production Rate | 5–50/h, depending on size. | Up to 200/h, very high production rates. |

| Dimensional Accuracy (Tolerance) | Achievable allowance: ±0.25 to ±0.75 mm. | Achievable allowance: ±0.05 to ±0.35 mm. |

| Surface Finish | Good (0.8–6.3 µm). | Excellent (0.4–3.2 µm). |

| Complexity | Complex internal geometries possible using semi-permanent processes (sand cores). | High complexity possible, but limited by movable core design; complex internal features are challenging. |

Comparing these two methods is akin to comparing pouring water into a bottle versus using a high-powered hose to fill it. Gravity casting (permanent mold) is slower and relies on the fluid’s natural flow properties, yielding strong mechanical properties and allowing for complex internal structures via auxiliary cores. Pressure die casting, utilizing extreme force, rapidly fills the mold, allowing for thinner walls and finer surface detail, making it the clear choice for mass production where speed and high surface quality are paramount.

If you are looking for castings with complex internal geometries, good surface finish, dimensional accuracy, reduced porosity, and exceptional strength-to-weight ratios feel free to reach out to your new manufacturing partner here at ProCast Technologies. Contact us today for your single source, high-quality, on-time casting solution partner.