Permanent mold casting is a versatile manufacturing technique used primarily to produce components that require excellent consistency and mechanical properties. It relies on reusable metal molds to create dimensionally accurate parts serving critical functions across diverse industries. Understanding the material properties, the mechanics of the process, and its economic factors is essential for maximizing its effectiveness.

This article investigates the primary uses and advantages of this method, linking directly to its broader applications discussed in Permanent Mold Casting Applications and the main topic, Permanent Mold Aluminum Casting.

What is permanent mold casting?

Permanent mold casting is a defining metalworking process that uses metal tooling, typically made of steel or cast iron, to form parts. Unlike expendable mold methods like sand casting, the mold itself is reusable across thousands of cycles. This high reusability makes it an economical and high-quality alternative to Sand Casting.

The resultant products feature superior surface finishes and dimensional accuracy, which reduces the need for extensive post-casting machining. This method is commonly employed for aluminum and other light alloys.

What is Permanent Mold casting used for?

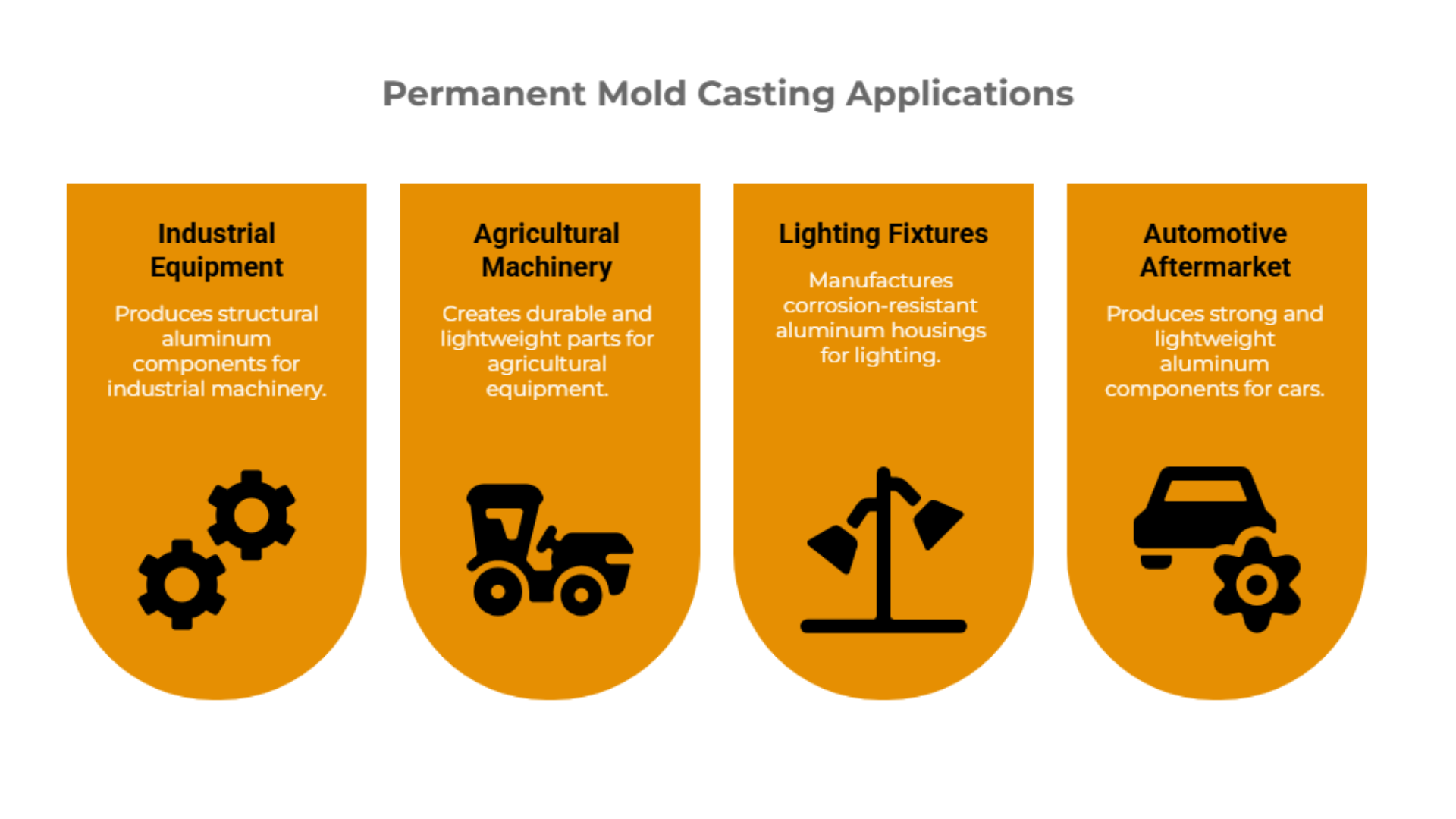

What aluminum casting is used for? This versatile manufacturing process produces structural aluminum components across diverse industries that require an exceptional strength-to-weight ratio, durability, and corrosion resistance. Key applications include industrial equipment, agricultural machinery, lighting fixtures, and automotive aftermarket components. These sectors specifically choose aluminum casting because the material’s inherent properties—lightweight construction combined with superior strength and long-term corrosion resistance—deliver optimal performance in demanding operational environments.

As a mineral fundamental resource, aluminum is the most abundant structural metal, comprising 8% of the earth’s crust. The need for lightweight components in the automotive and aerospace fields ensures that aluminum casting remains essential for modern structural parts.

The design criteria for permanent mold castings demonstrate the need for structural precision and optimal flow characteristics:

What is a permanent mold casting process for metal?

Describing in more depth what is a permanent mold casting process for metal involves, it involves securing the permanent mold, introducing the molten metal, and allowing it to solidify before the part is ejected. The process can utilize either static pouring or tilt pouring, involving rotation of the mold during filling to minimize turbulence and improve flow consistency.

The development process for a new casting involves an iterative design process, where the initial casting geometry may be repeated several times via simulation before production standards are met. This process is highly dependent on achieving optimal crystallization conditions and managing metal flow properties within the mold.

Can sand cores be used in permanent mold?

Sand is used in casting in non-reusable molds or as specialized cores within the permanent metal mold. The semi-permanent mold process utilizes aluminum sand casting foundry practices, where sand cores are used to create complex internal features and undercuts that cannot be achieved using metal molds alone. The sand cores are placed into the metal mold before pouring and are broken out once the casting has solidified.

Is aluminum casting expensive?

The question of is aluminum casting expensive depends largely on production volume and tooling requirements. The initial investment in the reusable steel or cast iron tooling is meaningfully higher than the tooling cost for expendable sand molds. However, for medium annual volumes typically ranging from about 500 to 50,000 pieces, the permanent mold process becomes highly economical.

Permanent mold casting production rates are often not comparable to other methods, making them an efficient choice for large quantity production. Furthermore, approximately 30% of the material going into new components is of a secondary kind, such as recycled aluminum. This efficient recycling contributes considerably to cost-effectiveness and reduces raw material dependence.

How big is the aluminum casting market?

How big is the aluminum casting market? It’s remarkably large in excess of $100 billion dollars annually and steadily expanding. Growing demand for lightweight solutions in transportation and industrial machinery continues to drive growth, supported by ongoing advancements in alloy development and casting techniques that reduce segregation and porosity while enhancing mechanical performance.

Advances in aluminum solidification science have made direct casting of complex shapes a viable method, enhancing competition with traditional forging processes for critical structural applications. Continued technological investment in CNC machining and heat treating capabilities ensures this industry maintains its high-quality standards and future growth projections.

Conclusion

Permanent mold casting is a reliable, quality-focused process that provides durable, structurally sound components for medium to high volume needs across industrial and specialized sectors. By leveraging reusable molds, it overcomes the limitations of temporary molding processes, yielding superior surface finishes and dimensional accuracy at a competitive unit cost. The quality inherent in this casting methodology is paramount to its continued importance in manufacturing high-performance aluminum parts.

To explore more expert insights on how to optimize your casting methods, material selection, and stay abreast of industry trends, visit our website today and discover how our team here at Procast can help you stay ahead in the Permanent Mold Aluminum Casting market.