What are the tolerances for permanent mold castings?

December 12, 2025

Dimensional precision in metal components is essential for ensuring successful manufacturing processes and product reliability. When working especially with custom aluminum components, the ability to achieve tight specifications relies heavily on selecting the correct casting methodology. The permanent mold process is highly regarded for its superior accuracy, utilizing reusable metal molds capable of delivering consistent precision with each part crafted.

If you are ready to dive deeper into the technology of Permanent Mold Aluminum Casting, this guide will explain the tolerance standards that define this precise manufacturing method.

What are the tolerances for permanent mold casting?

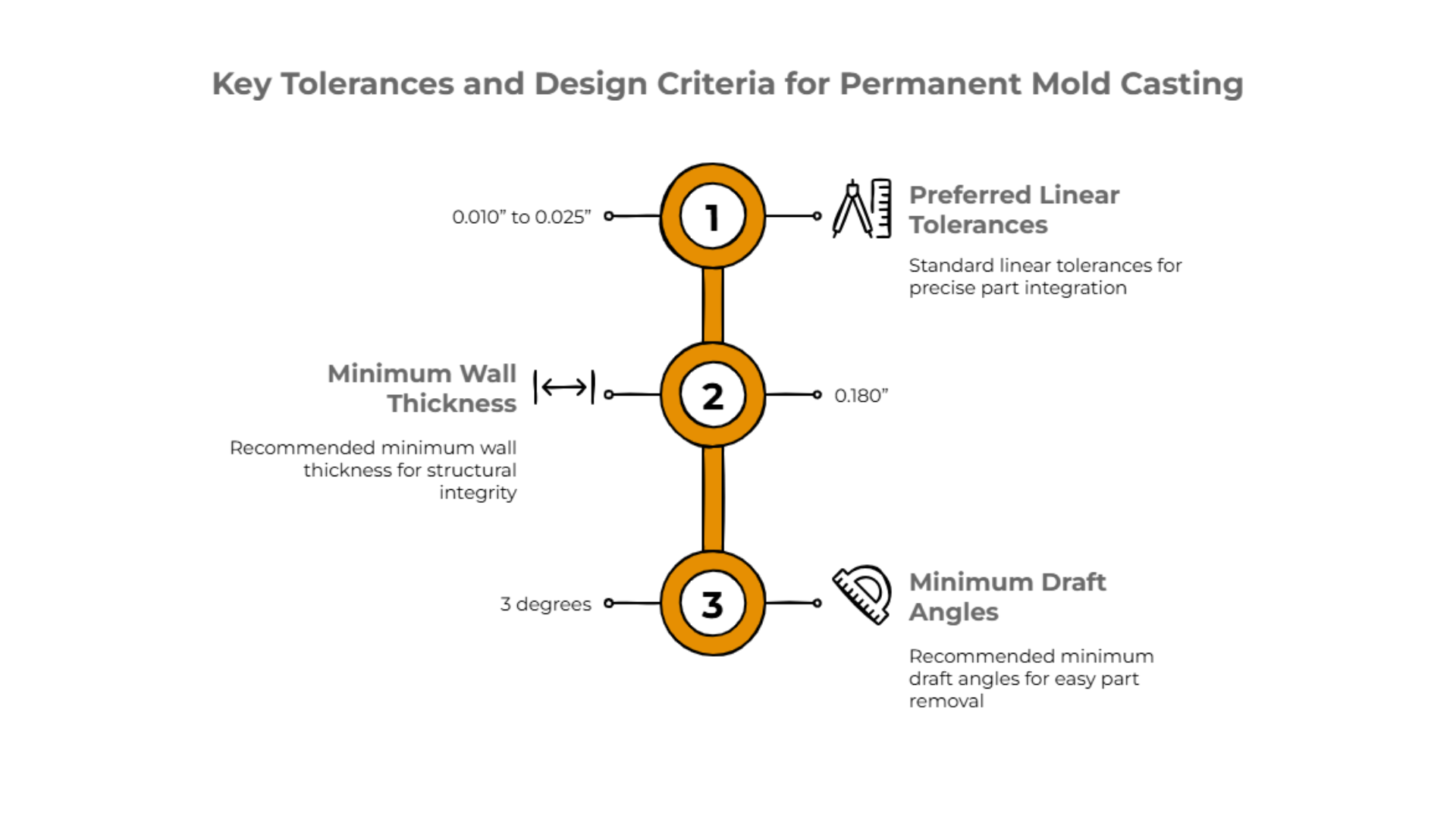

Permanent mold casting tolerances are substantially tighter than those achieved through simpler gravity casting methods such as sand casting, providing excellent dimensional control for complex parts. For standard applications, preferred linear tolerances range from 0.010” to 0.025”. This narrow range ensures precise integration of critical components into downstream assemblies, particularly in industrial equipment and high-performance applications where fit and function are essential. The utilization of durable, rigid metal tooling that maintains its shape and consistency across the production run is critical to achieving these tight specifications.

Linear Tolerances

0.010” – 0.025”

Minimum Wall Thickness

0.180”

Minimum Draft Angles

3 degrees

Tolerances are intrinsically affected by several factors, including the specific aluminum alloy selected and the overall complexity of the part geometry. To accurately determine what is the tolerance for permanent mold casting involves adherence to design criteria typically specifying a minimum wall thickness of 0.180” and recommending minimum draft angles of 3 degrees. Additionally, tighter specifications may be achieved through secondary operations like CNC machining. The application of these tight tolerances is critical in industries such as electrical transmission, defense, and railway components, where exceptional accuracy in fit and finish is required.

What is the tolerance for Sand casting?

Casting manufacturing tolerance generally refers to the accepted deviation in dimensions for components produced via foundational casting techniques. Tolerances are important for product quality, ensuring parts meet the geometric design criteria and function reliably. In the broader context of casting, the quality of tolerance often correlates directly to the rigidity of the mold material. Single-use sand molds, as used in methods like sand casting, naturally yield wider (looser) tolerances due to the lower structural stability of the mold material compared to the reusable molds employed in the permanent mold process.

The ability of rigid metal molds to resist deformation and ensure dimensional consistency makes permanent mold casting well-suited for high-precision applications. This stability is particularly advantageous for medium-volume projects, specifically ranging from 500 to 50,000 pieces annually, ensuring both efficiency and cost-effectiveness across production runs.

When a part requires tight external tolerances while featuring complex internal passageways, the semi-permanent mold process can be employed. This variation uses sand cores within the permanent metal mold to achieve intricate internal geometries that would otherwise be impossible to cast.

When assessing manufacturing options, using the superior dimensional accuracy afforded by permanent molds is key to achieving a successful product that minimizes downstream corrective work and assembly issues. Adherence to strict sand casting tolerance standards is often complicated by the mold’s tendency to shift during pouring, whereas the permanent mold process offers reliable dimensional stability.

What type of casting is the most popular and simplest?

Sand casting is widely considered the most popular and simplest casting method due to its universal adaptability across nearly any metal or alloy and low initial tooling cost. Its primary advantage lies in the use of internal cores to accommodate components of nearly any size and shape, including those with highly complex internal geometries. However, simplicity and popularity often necessitate compromises in the resulting dimensional accuracy and mechanical properties.

Conversely, the permanent mold process is highly favored when quality, precision, and material performance are essential. While sand casting offers maximum versatility, the permanent mold process provides superior dimensional accuracy, surface finishes, and strength-to-weight ratios.

For manufacturers prioritizing reliability and mechanical integrity, the permanent mold process often represents the best aluminum casting mold material option. The quality control inherent in the process promotes confidence in producing durable, high-integrity parts. The selection of aluminum itself can be viewed as an investment due to the large amounts of energy required to extract it from its oxide. Using a high-precision casting method, such as permanent mold, protects this investment by ensuring production of final components of lasting value to meet demanding structural requirements.

What is the disadvantage of sand casting?

The primary disadvantage of sand casting is the lower dimensional accuracy and inferior surface finishes of its output relative to precision methods like permanent mold casting. This lack of dimensional control may increase the need for post-cast machining to refine the part’s dimensions and surface quality. This inevitably increases both the manufacturing time and overall cost of production.

| Feature | Permanent Mold Casting | Sand Casting |

|---|---|---|

| Dimensional Accuracy | High (Tight Tolerances) | Low (Loose Tolerances) |

| Surface Finish | Superior | Inferior (Requires Finishing) |

| Mechanical Strength | High | Lower |

| Tooling Cost | Higher (Reusable Molds) | Low (Single-Use Molds) |

| Production Volume | Medium (500 – 50,000/yr) | Low to High (Versatile) |

In addition, loose tolerances in sand casting can negatively impact the mechanical strength and performance of the component. For structural applications where cast material is subjected to high loads, fracture strength, and fatigue resistance, sand casting can fail to meet technical requirements. If the design requires that components withstand high mechanical stress, quality concerns associated with sand casting make it an unacceptable choice.

Therefore, designers must carefully evaluate permanent mold casting advantages and disadvantages early in the product development stage, weighing the factors of desired function, achievable production, and material properties. When precision and reliability are paramount, the permanent mold process consistently triumphs over the disadvantages of sand casting’s inherently wider tolerances.

Conclusion

The permanent mold process provides a necessary solution for manufacturers who require consistent precision, dimensional accuracy, and superior material strength. By delivering extremely tight tolerances, this method ensures that aluminum components are reliable and fit flawlessly into complex assemblies, confirming the process’s value for high-quality production.

Ready to dive deeper into the industry of Permanent Mold Aluminum Casting? Connect with Procast today for expert insights, tips, and the latest industry trends that can help elevate your projects.